ABOUT THE CAROSUNG

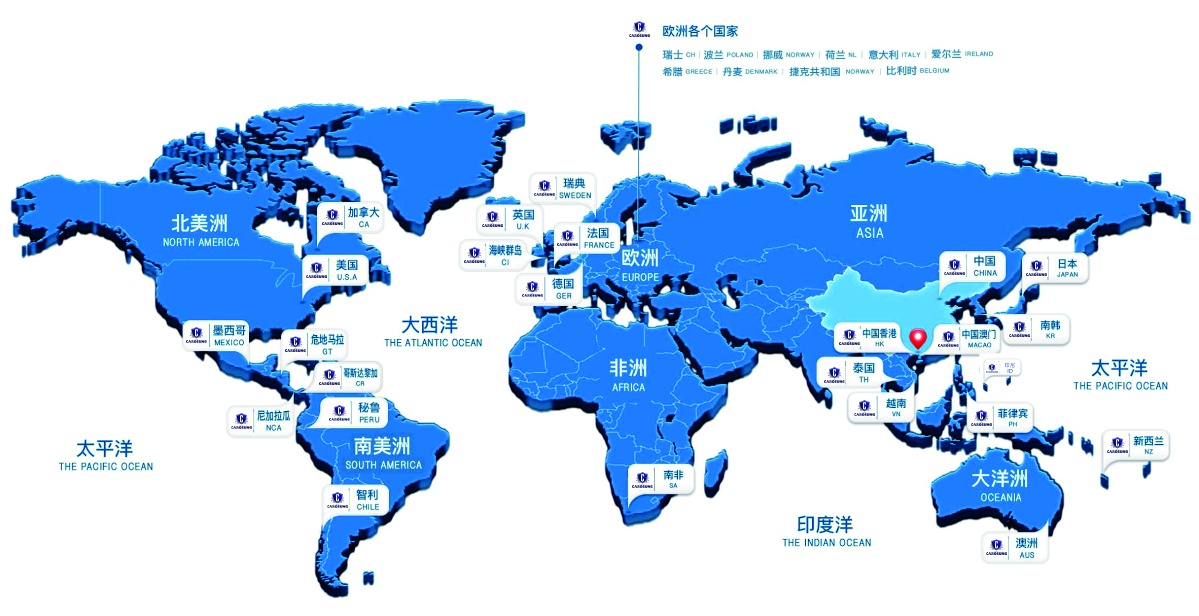

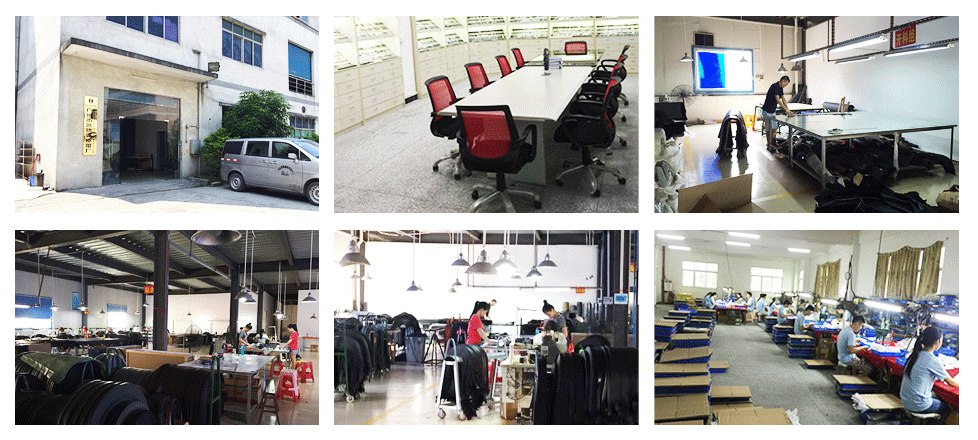

Established initially as Lifeng Hardware Co. Ltd in 2005, we began to produce custom belts for the global market. Continuously pushing the envelope forward, we developed a mature supply chain, elevated our production process, and offered various value-added services to become the one-stop shop for clients. In 2016, wanting to strengthen our presence in the market, we’ve developed our own brand, Carosung.

2005

Founded in 2005

20+

more than 20 years of OEM experience

60+

60+ new items/month

24+

24 hour online

50-100+

50+ workers on duty

50+

Die casting machine/CNC machine/laser welding machine/polishing machine

1,000,000

More then 1,000,000 molds